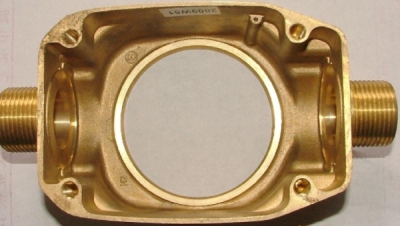

Brass Die Casting

We offer high temperature die-castings using brass casting alloys. Sizes ranging from less than 1 oz. to 10 lbs. are available.

Features of brass castings: Corrosion, abrasion, wear resistance, temperature resistance, and electrical conductivity.

Applications of brass casting: electric motor components, architectural hardware, decorative hardware, locks and door handles, enclosures, fluid metering, control equipment, plumbing hardware, lighting fixtures, fire protection devices, bearing sheaves.

Comparing to Zinc and Aluminum, Brass Die Casting requires higher temperature, thus requires better mold steel. Mold also need to be kept at warm temperature to avoid disruptive temperature change. Mold steel choices can be H13 or SKD61 or Swedish 8407.

The appilcable ASTM standard for copper casting is ASTM B176-04. Suitable Copper Materials are

Copper-Zinc Alloy: C85700, C85800, C86500, C87800 - Typically 55-60% copper, 30-40% Zinc.

Copper-Zinc-Manganese Alloy: C99700 and C99750 - Typically 55-60% copper, 20% Zinc, 11 - 23% Manganese

Some copper pieces might be better forged than die castied. When in doubt, please consult with our engineering staff.